Solderable Case Study

Solderable Case Study

Sealing a Liquid Crystal Display

Customer's Problem

An exceptionally non-contaminating hermetic seal was needed to seal the fill hole of a liquid crystal device. Epoxies and other resins either polluted the liquid crystal or failed to bond perfectly to the glass. They all allowed the migration of water into the liquid crystal fluid rendering the display non-operational.

Failure Mode

Virtually all organic resins will slowly transmit moisture either by capillary action or chemical transfer. When the sealed volume is very small, the amount of water needed to destroy the device is incredibly small.

Coursen Coating Labs Solution

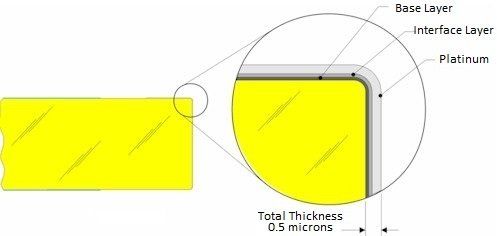

The area around the fill hole was coated with a platinum solderable system, type 2LPT. The parts were sent to coating after assembly firing with no further cleaning required. The filled parts were soldered in air with 60-40 lead tin solder, using no flux. The trace of liquid crystal fluid near the hole acted as a flux.

CoursenCoating Lab's Solution

The customer wanted to continue with lead/tin solder in a non-reducing atmosphere; a coating plan consistent with the process was required. Platinum was chosen since it does not oxidize or dissolve rapidly in solder. A bonding layer of cermet, which adheres very well to most glass and ceramic materials, was used below the platinum. This coating adhered well and soldered well, but ripped out a layer of the substrate after thermal cycling. A third layer of expansion matching material was then included in the system to reduce stress in the joint.

Applications

- Guidance and Tracking Systems

- Passive IR Detectors

- Fiber Optics

- Aerospace